|

Clean Association of TOKYO 23

|

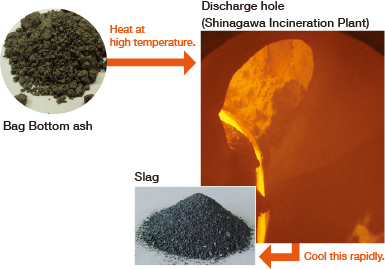

What is slag?

When the bottom ash from combustible waste is melted at a high temperature of over 1,200 degrees Celsius and rapidly cooled, the material turns into sandy slag.

As slag, the volume is almost half of that of ash and approximately one-fortieth of its original state as waste.

The process of making slag decomposes dioxins within the ash and traps in the heavy metals, which make it safe to be used for construction material.

Mechanism of ash melting

The Clean Association of TOKYO 23 has the following four different types of ash melting furnaces.

| Electric melting furnaces | Fuel type | ||

|

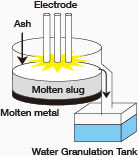

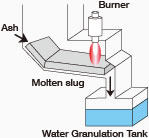

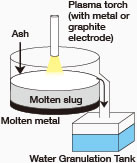

Alternating current arc type Application of high voltage to an electrode induces an electric arc between the electrode and the molten metal. The resulting heat melts the ash. |

|

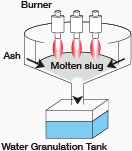

Surface melting(radiant type) Town gas or other fuel is burned using a burner to melt the ash from the surface in contact with the burning flame. |

|

Plasma type (with a metal or graphite electrode) A plasma is created on a cylindrical electrode under high voltage air, etc. The temperature of the plasma is high enough for its heat to melt the ash. |

|

Surface melting (rotating type) The outer cylinder of the furnace integrated with the bottom rotates to evenly distribute the ash. The ash is then melted through exposure to flame. |

List of ash melting facilities

| Itabashi | Adachi | Setagaya | Katsushika | Chubo | Shinagawa | Tamagawa | |

| Processing Capacity | Two 90-ton furnaces | Two 65-ton furnaces | Two 60-ton furnaces | Two 55-ton furnaces | Four 100-ton furnaces | Two 90-ton furnaces | One 30-ton furnaces |

| Type | Electric type | Fuel type | |||||

| Alternating current arc type | Plasma type (with a metal electrode) | Plasma type (with a graphite electrode) | Surface melting (radiant type) | Surface melting (rotating type) | |||

(as of December 2011)

Slag is used beneficially

Because slag has properties that resemble sand, it can be used widely as a construction material such as skeletal material or backfilling of asphalt pavements or secondary concrete products.

Recorded use for FY2010

| Organization used | Supplied amount | Main uses |

| 23 cities | 6,163 | Asphalt pavement material, backfilling, etc. |

| Clean Association of TOKYO 23 | 18 | Asphalt pavement material |

| Tokyo Metropolitan Government | 70,806 | Ground improvement material |

| Government, private companies, others | 191 | Pavement material, etc. |

| Total | 77,178 |

(Unit: Tons)

Clean Association of TOKYO 23 is working to enable all slag produced to be used as a resource. It is currently developing applications, accumulating case examples, and creating a system that allows easier use, while petitioning the 23 cities, the Tokyo metropolitan and national governments and private companies to use slag.