|

|

The Eco-Cement Project aims at shifting

from final disposal of waste to resource recycling based

on its active use as resources.

Incineration ash generated from incineration of waste that comes from 26 cities in the Tama area is recycled into “eco-cement.”

The Tokyo Tama Regional Association for Waste Management and Resource Recycling is working on the Eco-Cement Project together with the Hinode-machi Town Government with a view toward building a sound material-cycle society.

What is eco-cement?

Eco-cement is a new type of cement produced from incineration ash resulting from waste incineration. Its name was derived by combining the words “ecology” and “cement,” since it is environmentally friendly, based on the use of waste as a resource.

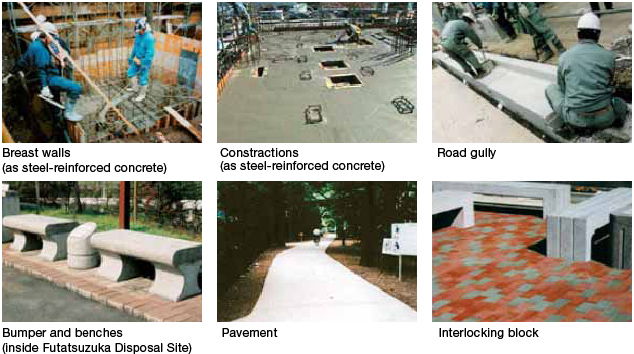

Incineration ash has a high content of substances essential to cement, and a new technology was invented for using it as a material for cement. In July 2002, the Japanese Industrial Standard recognized it under the name eco-cement. Comparable with ordinary cement in terms of quality, eco-cement can be broadly used in civil engineering projects and various concrete products.

Objectives of eco-cement project

1. Further advance recycling in the Tama area

Incineration ash had previously been subject to final disposal, and it is now reused in the form of cement. The project aims to bolster recycling in the Tama area, which has an advanced level of recycling.

2. Make long-term effective use of the Futatsuzaka Disposal Site.

After implementation of the project, incombustible waste alone is subject to final disposal, which helps massively prolong the service life of the Futatsuzaka Disposal Site.

3. Take more action for safe landfill.

Project approach

The facility is efficiently operated with the use of ideas and managerial expertise from the private sector.

Special knowledge and technologies are needed for construction of an eco-cement facility and for production and sale of eco-cement.

The Tokyo Tama Regional Association for Waste Management and Resource Recycling adopts the concept of private finance initiative (PFI) and takes the design/build/operate (DBO) approach to collectively contract with a private operator to engage in design, construction and operation of the eco-cement facility and in the sale of eco-cement.

For 20 years, operational services including operation, maintenance and management of the facility and sale of the eco-cement have been outsourced to TOKYO TAMA ECOCEMENT Inc.

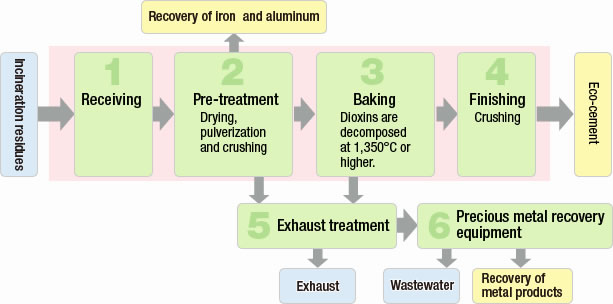

How to produce eco-cement

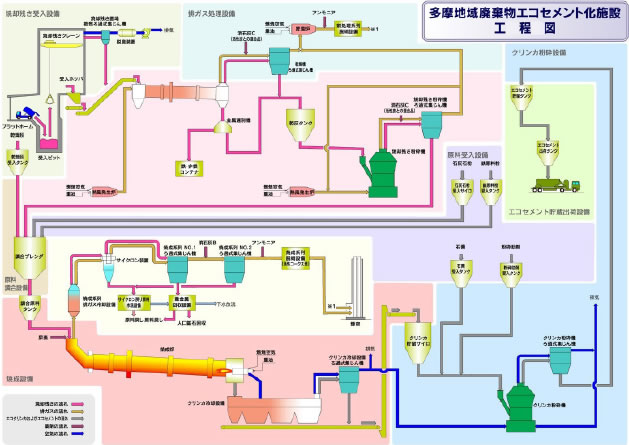

The ashes from incinerated waste undergo the preliminary processes of dehydration, collection of iron/aluminium, and pulverization. Then, subsidiary materials (limestone, iron) are added and mixed together as the raw materials for eco-cement. The compound raw materials of the eco-cement are calcined into clinkers, which are the intermediate products of cement. Finally, the materials are pulverized after adding gypsum to produce eco-cement.

The exhauset gases emitted in the eco-cement production processed properly and then discharged into sewerages.

Eco-cement production process chart

Eco-cement application examples

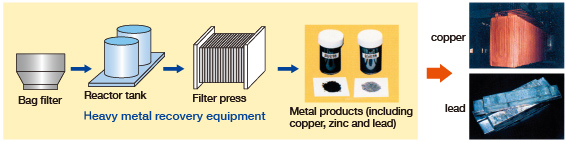

Heavy Metals Recycling and Environmental Conservation Efforts

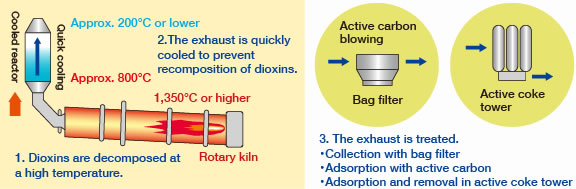

Treatment of dioxins and heavy metals

Incineration ash is blended with limestone and baked into eco-cement at a high temperature of at least 1,350°C. Dioxins are decomposed in the process of high-temperature treatment in the incineration furnace. The exhaust generated from this process is quickly cooled to prevent recomposition. The bag filter is also used for safely treating the exhaust. The eco-cement production takes place inside a closed facility, which eliminates the risk of ash flying up. Heavy metals recovered are conveyed to refineries for recycling. The system tirelessly pursues not only safety of the production process but also reuse of resources.

Principal pollution control measures for the eco-cement facility

Air pollution control

The facility is equipped with the latest exhaust treatment system to meet voluntary standards more stringent than those in the statute.

Odor control

Incineration ash is received in the building. The air in the pit is subject to suction and deodorization treatment. No odor leaks out of the facility.

Noise and vibration control

Any system that generates noise or vibration is installed indoors or equipped with a silencer to prevent the noise and vibration levels from exceeding the statutory limits.

Water contamination control

Wastewater is treated to reduce the contamination concentration to the sewerage discharge standard prior to actual discharge to the public sewerage.

Dioxins control measures for the eco-cement facility

Recovery of heavy metals at the eco-cement facility