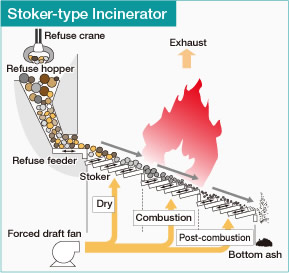

Stoker-type incinerator

Waste is gradually conveyed on the stoker to subsequent steps. The treatment is divided into three processes: The dry process evaporates the water content in the waste, the combustion process powerfully burns the dried waste and the post-combustion process completely burns it out.

Waste is gradually conveyed on the stoker to subsequent steps. The treatment is divided into three processes: The dry process evaporates the water content in the waste, the combustion process powerfully burns the dried waste and the post-combustion process completely burns it out.

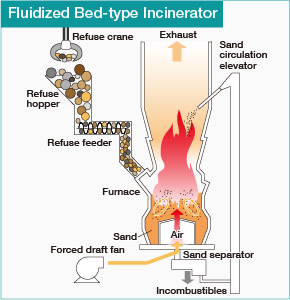

Fluidized bed-type incinerator

Air blowing from the bottom into the sand-filled furnace causes the sand to move vigorously like boiling water. In this state, the sand is heated and waste is put into the furnace so that it can be incinerated.

Air blowing from the bottom into the sand-filled furnace causes the sand to move vigorously like boiling water. In this state, the sand is heated and waste is put into the furnace so that it can be incinerated.

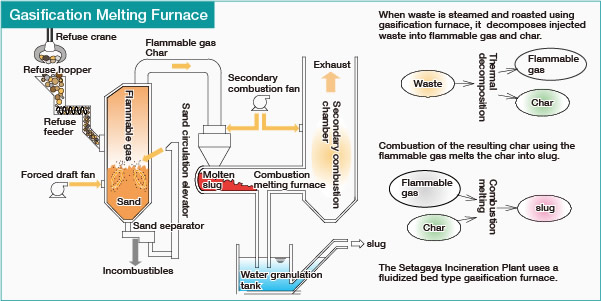

Gasification melting furnace

When waste is steamed and roasted using gasification furnace, it decomposes injected waste into flammable gas and char. Combustion of the resulting char using the flammable gas melts the char into slug. The Setagaya Incineration Plant uses a fluidized bed type gasification furnace.